By Sara Mathov, David Anderson, Head of Service Project Support, and David Escobar, Director R&D, Valmet Flow Control Business Line

Most of the existing literature on this topic calls attention to proper valve specification. This article, however, will focus on considerations of cleanliness including keeping valves oil, grease, and contamination-free at factory, at site and after maintenance.

Valmet’s flow control business line follows strict cleaning, inspection, and testing procedures to meet industry standards and customer requirements. Valve factories are evaluated and validated against these procedures at least once a year. Valmet also works closely with licensors, skid manufacturers, and end users to promote good practices.

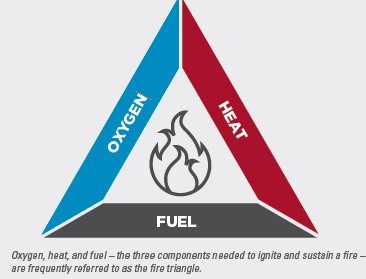

Oxygen Fire Hazards

Oxygen is not flammable by itself but supports and accelerates combustion. Oxygen concentrations greater than 23.5% create a special fire hazard. There are three elements necessary for an oxygen valve fire to occur: oxidizer (oxygen), ignition source, and a flammable material (fuel).

In an oxygen-enriched environment (oxygen concentration in the range of 23.5 – 100%), the oxidizer is present at all times, so it is important to understand the potential ignition sources and mechanisms present in the valve. It is also important to know the limits for oxygen compatibility of the materials used for the valve components and lubricants because in the event of ignition, even the metal of the valve can become the fuel.

The following ignition mechanisms must be considered in a gaseous oxygen service when the contributing factors are present1:

- Particle impact

- Adiabatic compression heating

- Promoted ignition/kindling chain

- Mechanical friction

- Mechanical impact

- Thermal ignition

- Electrical arcing including static discharge

- Resonance

- Flow friction

Importance of Cleanliness

There are two types of contaminants, non-volatile residue (NVR) and particulate. If a valve for oxygen service is not cleaned to an appropriate level, there may be concerns of ignition of NVRs by adiabatic compression, or other mechanisms and ignition of metallic particles by particle impact.

Hydrocarbon-based greases and oils, organic compounds, nitrates, phosphates, water-based detergents and cutting oils, some acids and solvents, metallic particles from rust or machining chips, lint, fibers, dust, weld slag, metal grindings and fillings, are all common contaminants in piping systems.

ASTM G93, harmonized CGA G-4.1 and EIGA IGC Doc 33-18, and MSS-SP-138 provide excellent recommendations for cleaning processes, inspection methods, and various levels of cleanliness requirements.

Mechanical Cleaning

Hot water and steam cleaning is most effective against oil, grease, dirt, loose scale, welding and brazing residues, and other contaminants. The addition of detergents can improve the performance of this cleaning method.

Alkaline cleaning uses caustic salt suspended in water to create a highly alkaline solution. It is effective against hydro-carbon oils, grease and waxes, and generally is enhanced by agitation or jet spraying. Typically, this is used for industrial parts washers. This process is greatly enhanced by ultrasonic agitation, but the solvent residue must be removed to prevent corrosion on some metallic materials.

Acid Cleaning

• Hydrochloric acid is used to remove scale, rust and oxides, and to strip platings (chrome, zinc, cadmium, etc.) and other coatings.

• Chromic and nitric acid are used for passivating, deoxidizing, brightening, and removing alkaline residues in addition to cutting oils.

• Phosphoric acid removes oxides, light rust and fluxes.

• Acids must be removed completely from the part prior to drying and, depending on the acid strength, may need a neutralizing process.

Detergent cleaning is performed using water solutions containing chemicals that have different functions. It is normally performed in an alkaline environment for better degreasing efficiency.

Semi-aqueous Cleaning

Solvent cleaning removes organic contamination from the part surface. Solvents used for oxygen cleaning can include acetone, isopropyl alcohol, and more. Alcohol is a common solvent often used to revisit areas of concern identified by black (UV) light inspection. Solvents like alcohol evaporate completely, leaving no residue.

Vapor degreasing is a process in which a solvent is heated until it vaporizes, while the part is maintained at a lower temperature. The solvent then condenses and dissolves contaminants. The part must be oriented so that the condensed solvent can drain from the part by gravity. This method is very effective for inaccessible areas on parts but requires a contained environment for the part during the process.

Inspection Methods

Qualitative methods include a direct visual inspection with white light.2 This is the most common method to detect the presence of contamination such as oils, greases, preservatives, weld slag, and chips. This method can be used to detect particulate matter greater than 50 microns and moistures, oils, greases, in relatively large amounts (for instance, 500mg/m2 of hydrocarbon on stainless steel surfaces).

Direct visual inspection is conducted with ultraviolet light. This method is only used after visual inspection with white light. A wipe test is designed to identify contaminants in locations that have no direct line of sight. A clean, lint-free non-fluorescing cloth is used to lightly wipe the surface, and then both white light and UV light are used to inspect the cloth.

A water break test is sensitive for detecting low contamination levels of oil and grease on the surface, and a solvent extraction test is done by evaporating the solvent used for cleaning and obtaining the weight of the remaining effluent. Knowing the surface area of the part being cleaned allows one to derive the weight of residue per unit area which is the cleanliness level. Acceptable levels of residue vary according to user requirements.

Particular attention should be given to storage, handling and installation at site. Projects may face delays. Valve ownership may change hands. Contractors may involve sub-contractors who also need to be trained on oxygen risks and proper handling and installation practices.

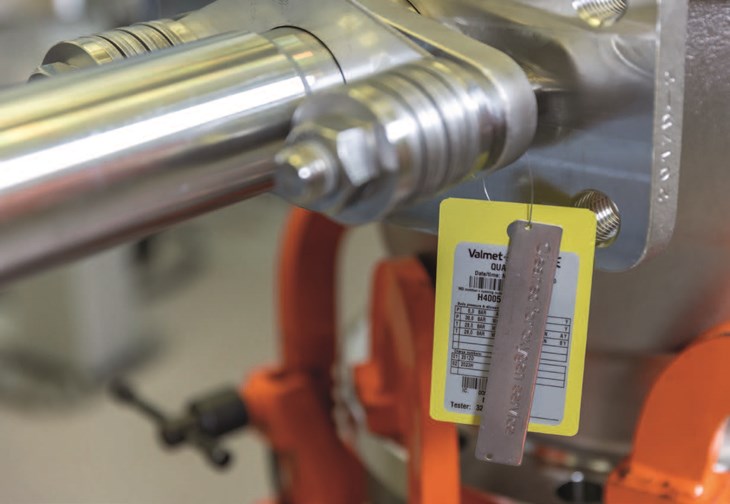

Factory-attached tags should also be re-checked to ensure that the valve is identified as having been processed for oxygen service, and that the valve type and material conform to requirements of the service intended.

No Compromises

Considering whether accessories can be added to the valve and set up without violating the protection are also essential. If the protection is compromised, are there procedural steps to identify and remediate any contamination? Are suitable facilities, tools and competent personnel available?

For these reasons, Valmet recommends having its flow control commissioning or service specialist at the site to help promote and monitor good practices. This will also help ensure any situation where protection is compromised is adequately and speedily addressed.

Operation and Maintenance

Maintenance of oxygen service valves should only be performed by personnel trained in oxygen risks. Valves should only be reassembled in a clean area using oxygen-compatible lubricants.

For instance, a clean room provides a designated location where the environment limits dust airborne particles, and where clean tools, assembly, and test equipment can be stored. It can also provide controlled lighting for visual inspections. Every effort must be made to ensure that valves returned to oxygen service are dirt, oil and grease-free.

Valmet’s Flow Control Service Centers

However, further handling can contaminate these spare parts and it is the responsibility of the company that ser-vices the valve to ensure the parts and the valve is properly cleaned and inspected, before the valve is installed back in the pipeline.

For these reasons, Valmet recommends oxygen service valves to be sent to Valmet’s flow control service center, or an authorized service partner. Several of Valmet’s flow control service centers are equipped with a dedicated controlled area and clean test equipment. Alternatively, the company has internal procedures in place which allow for oxygen cleaning in a temporary clean room, at a service center or at the site, such as during maintenance shutdowns. The company’s service specialists can also clean oxygen valves in the customer’s own clean room. Valmet’s flow control technicians are internally certified in oxygen valve cleaning, and competency is refreshed and validated every two years.

Risks and Challenges

REFERENCES

- Harmonized CGA G-4.4 and EIGA IGC Doc 13-12, “Oxygen Pipeline and Piping System”

- Harmonized CGA G-4.1 and EIGA IGC Doc 33-18, “Cleaning of Equipment for Oxygen Service”