It is required that monitoring with such tools should provide “leak – no-leak” classification data for each component in the facility, which with the use of component-level average emission factors (EFs) gives the total quantity of fugitive emissions for the facility. There are EFs derived for conventional gas analyzers (“sniffers”) and for optical gas imaging (OGI) cameras, but yet there are no EFs for handheld Tunable Diode Laser Methane detectors (TDL detectors). The article presents the results of experiments conducted to fill this gap.

Background

Requirements for LDAR plans and fugitive emissions quantification methods were initially designed by the US Environment Protection Agency (EPA) Protocol and then included in Compendium by the American Petroleum Institute (API). The corresponding standard for fugitive emissions quantification in the European Union is EN 15446:2008. EPA also published a guide for companies implementing obligatory and voluntary LDAR programs. LDAR programs require building an inventory of all components being a potential leak source and then establishing periodic instrumental monitoring of components. Components are defined as any non-welded connections: flanges, valves, pump seals, open-end lines, etc. Detected leaks are subject to repair. Components inventory provides data for fugitive emissions baseline calculation of the asset with the average emission factors approach described in EPA Protocol, Section 2. Screening data collected at facility monitoring is used for calculating the actual emission volume of the facility. The efficiency of the LDAR program is evaluated in terms of absolute and relative emission reduction. Reduction is the difference between the baseline fugitives’ emissions volume and the actual emission volume. The quantification method, i.e. actual emission volume calculation, depends on the monitoring tool used and the screening data collected.

A classical well-known tool for LDAR monitoring is the gas analyzer (“sniffer”), able to measure methane concentration. The operator with a sniffer should put the sniffer probe at the leak interface of the component and measure the concentration precisely, as described in EPA Method 219. Screening values for all components are collected. Then one can use one of the approaches for fugitives emission quantification, also developed by EPA: 1) approach based on leak threshold at 10,000 ppm definition with leak/no-leak EFs ( 5 section 2.3.2 p.2-18); and 2) approach based on EPA correlation equations to convert screening values in ppm to leak rates in grams per hour ( 5 section 2.3.3 p.2-24). The main advantage of using a sniffer is that this is a well-known, trusted, and widely recognized method. The main disadvantage is that this method is tedious and time-consuming.

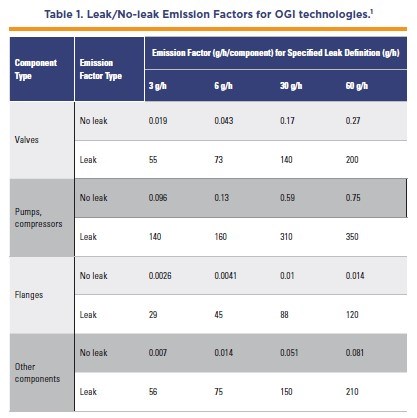

Another tool used for LDAR monitoring is Optical Gas Imaging (OGI) cameras. OGI cameras are passive infrared cameras sensitive to hydrocarbon gases. A leaking component is defined as any leak observed by an OGI camera. Asset fugitive emission quantification is based on using OGI leak/no-leak EFs, suggested by M. Lev-On et al. in 2012 and included in the Oil & Gas Methane Partnership (OGMP) Reporting Framework in 2017. The main advantage of OGI is efficiency: an OGI camera operator can check ten to twenty times more components per day than an operator with a conventional sniffer [14]. The main contra is that OGI cameras are still rather expensive.

Handheld and aerial laser methane detectors, also known as Tunable Diode Laser (TDL) detectors, are used for remote methane detection along with OGI cameras. TDL detector measures the intensity of the reflected laser beam and calculates the amount of methane in the beam path. TDL detector returns screening value in ppm × m units. Handheld TDL detectors are simple to use and efficient for methane detection. The operator with TDL detector points a laser beam at the component and reads the ppm×m value; if it is over a certain threshold, the operator gets an alert. The operator can check methane remotely at distances up to dozens of meters, keeping himself safe from potential hazards.

o-leak EFs for OGI can also be applied for LDAR monitoring with TDL detectors, whenever TDL detector ability to detect leaks over a given threshold is assured experimentally under known conditions.

In this paper experimental data collected at a range of distances by handheld TDL detector when observing a controlled leak from a sources imitating a valve and a flange will be shared. The authors concluded that at reasonable distances TDL detector can be considered as LDAR tool with leak definition threshold 30 g/h and over, so the corresponding EFs derived for OGI (Table 1) could be applied for the mass emission quantification.

- BP, “Sustainability report,” 2020

- Rosneft, “Rosneft Sustainability Report 2020”

- Equinor, “Sustainability report,” 2020

- CCAC, “Methane Guiding Principles,” 2017. [Online]. Available: https://www.ccacoalition.org/en/resources/reducing-methane-emissions-across-natural-gasvalue-chain-guiding-principles

- EPA, “Protocol for Emission Leaks Emission Estimates,” 1995

- API, “Compendium of Greenhouse Gas Emissions Estimation Methodologies for the Oil and Natural Gas Industry,” 2009

- EU Standards, “EN 15446:2008 Fugitive and diffuse emissions of common concern to industry sectors – Measurement of fugitive emission of vapours generating from equipment and piping leak,” 2008

- EPA, “Leak Detection and Repair. A best practices guide.,” 2007

- EPA, “40 CR par 60 Appendix A-7. Reference Method 21, Determination of volatile organic compound leaks, EPA 453/R95-017,” 1981

- A. Pajkovic, “Automated Optical Gas Imaging For Continuous Monitoring Of Methane Emissions,” Fugitive Emissions Journal, 2022

- EPA, “DRAFT Technical Support Document. Optical Gas Imaging Protocol. (40 CFR Part 60, Appendix K),” 2015

- M. Lev-On, D. Epperson, J. Siegell and K. Ritter, “Derivation of New Emission Factors for Quantification of Mass Emissions When Using Optical Gas Imaging for Detecting Leaks,” Journal of the Air & Waste Management Association, 2012

- OGMP, “Technical Guidance Document 2. Fugitives,” 2017. [Online]. Available: https://www.ccacoalition.org/en/resources/technical-guidance-document-number-2-fugitive-component-and-equipment-leaks

- T. Trefiak, “LDAR Case Study Comparison of Conventional Method 21 vs Alternative Work Practice (Optical Gas Imaging),” 2016. [Online]. Available: https://www.epa.gov/sites/default/files/2016-04/documents/20trefiak.pdf

- Rosneft, “Official press-release: Rosneft implements complex technology for methane leak detection.,” 2021. [Online]. Available: https://www.rosneft.ru/press/today/item/204803/

- Google, “Google Developers Crash-course. Classification: Precision and Recall,” [Online]. Available: https://developers.google.com/machine-learning/crashcourse/classification/precision-and-recall