Continuous monitoring systems can detect, localize, and quantify methane emissions in real time with a high degree of accuracy. Continuous monitoring systems are also relatively inexpensive, easy to use, and easy to deploy and scale. EPA noted in the recent OOOOb/c ruling that advanced detection technologies, such as continuous monitoring systems, “have the ability to detect fugitive emissions quickly, cost-effectively, and in a manner that may be less susceptible to operator error or judgment than traditional leak detection technologies”.

By Dave Levy, Marketing Manager – Qube Technologies

However, continuous monitoring outputs alone do not fix leaks, nor teach operators how to improve emission responses in the future. Leak detection and repair (LDAR) workflows must be proactive and methodical to capture the full benefit of real-time emissions data from continuous monitoring systems.

Historically, LDAR workflows have emphasized scheduled physical inspections in search of leaks irrespective of the presence of a leak. Depending on the regulatory jurisdiction, program and facility type, physical inspections must typically be performed 2 – 12 times per year. But even regulatory programs with high frequency inspection requirements such as Colorado’s Regulation 7 are not sufficiently instructive for operators to make systemic operational improvements that result in fewer and less severe emission events over time.

Proactive workflows are distinguished from reactive workflows by first determining if sites are operating as designed by comparing measured emissions against estimated emissions. Operators can use continuous monitoring data in combination with emission estimates to identify root causes of fugitive emissions before they occur, rather than simply respond to emissions when they occur, and implement more effective systems that prevent or limit similar leaks in the future.

Over time, these root-cause improvements can lead to significant emission reductions and lower operations and maintenance costs associated with LDAR.

Continuous monitoring systems produce continuous emissions data that are essential to proactive workflows because the data continually informs the workflow, which in turn continually improves all related emissions management processes and outcomes.

Alarms and Typical Alarm Review Workflows in a Continuous Monitoring System

Continuous monitoring system alarms are notifications sent to key operator personnel when a potential leak has been detected. Most continuous monitoring systems allow operators to set their own parameters for triggering alarm notifications, such as when specific emission volumes or emission rates over time are reached, and most enable the operator to define alarm parameters on a site-by-site basis.

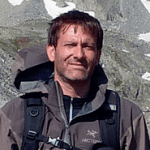

Continuous monitoring alarms will trigger operations and maintenance workflows designed to confirm the presence, severity, and source of an emission, and drive the appropriate remedial response. A typical alarm review workflow may look something like this:

Once an emission is detected, a prompt evaluation is made to either clear the alarm if the emissions falls within the range of normal operations, or to investigate further. If the cause of the alarm falls within normal operations and will be resolved in due course, no additional action is needed.

If further investigation is required, then a root cause analysis should be performed. If that analysis does not yield an explanation for the detected emission (an exception to the norm), then management should become involved, and the operator should continue with an AVO/OGI inspection. Once the cause of an alarm is determined and remedial steps are taken, an operator should annotate the event in the continuous monitoring system’s log.

Proactive Versus Reactive Emissions Management Workflows

While a reactive workflow will effectively resolve a one-off alarm and emission, it may not necessarily improve how operations and maintenance teams respond to or prevent similar events in the future. In effect, this reactive workflow does not make the operator any better the next time around.

A proactive workflow determines if sites are operating as designed by comparing measured emissions against estimated emissions every month. The workflow uses that analysis to improve the accuracy of emission inventories and various aspects of site design, operations, and LDAR practices for better emission reduction outcomes.

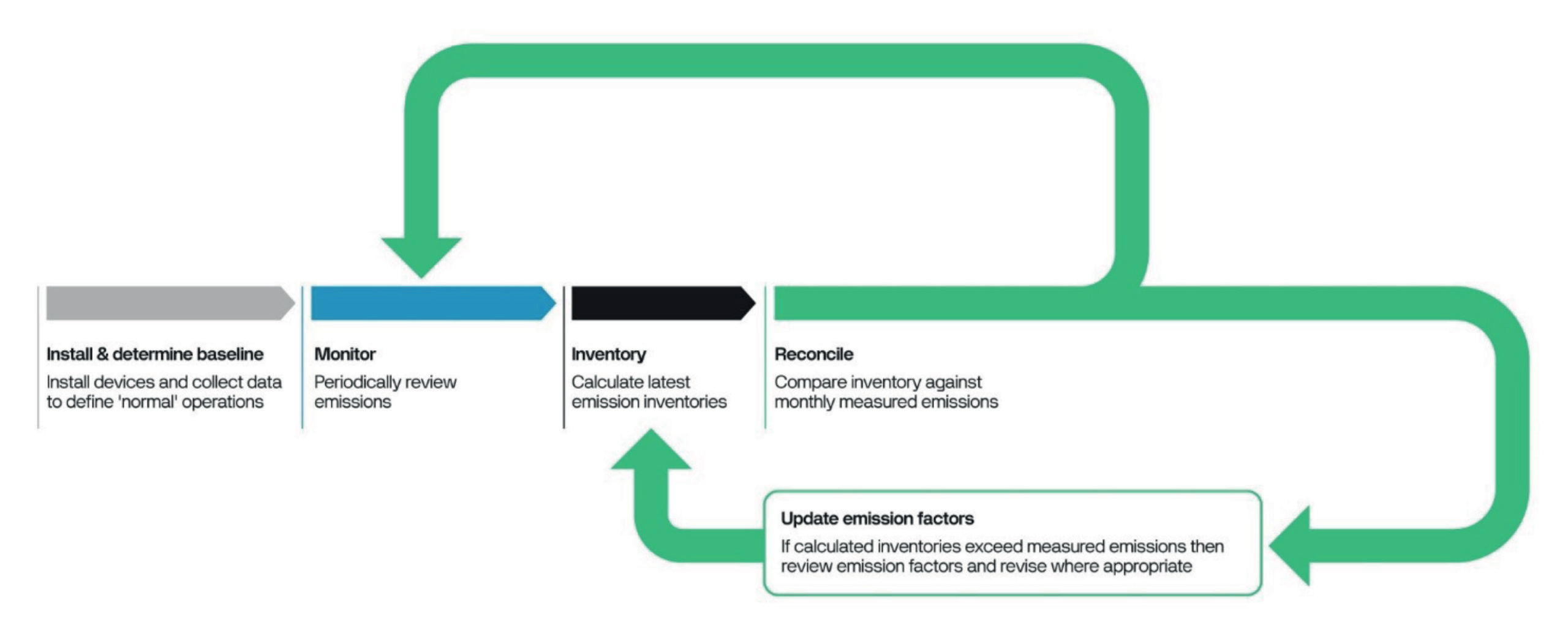

A proactive workflow is illustrated below.

In this workflow, continuous monitoring sensors are installed and collect data to determine the site’s emissions from normal operations (the emission baseline). Then, continuous monitoring data is used to create a measured monthly emissions inventory.

At the same time, a calculated inventory is developed using established emission factors for the site’s equipment and design. These inventories are then compared and analyzed through reconciliation. Reconciliation is an ongoing process of cumulative source-level emission inventories with independent site-level measurements to produce a more definitive emissions inventory. The reconciliation process helps improve the accuracy, thoroughness, and reliability of reported emissions, as well as workflows aimed at minimizing emissions.

In a proactive workflow, if measured emissions exceed calculated inventories, an operator should develop and implement operational and site design improvements before business-as-usual monitoring resumes. For example, an operator may implement design changes to conserve gas or send gas to flare as opposed to atmospheric venting during maintenance procedures, and by doing so limit the number of actionable emissions that occur at the site in the future.

This is an important branch in the workflow with financial consequences because an operator can make proactive changes based on learnings from data reconciliation instead of reactive changes to a major emissions event that is subject to the new methane fee.

However, if calculated inventories from emission factors exceed measured emissions, then an operator should review their emission factors and revise them where needed so they align more closely with measured emissions. EPA defines emission factors as “a representative value that attempts to relate the quantity of a pollutant released to the atmosphere with an activity associated with the release of that pollutant”. More simply, an emission factor is the pollutant emission rate relative to the level of source activity.

Emission factors are commonly used to prepare emission inventories and help operators identify and resolve operational inefficiencies. Since emission factors are calculated from averages of industry-wide data they may not, by themselves, produce accurate estimates for site-specific equipment and designs.

Continuous monitoring data can sharpen site-specific emission factor estimates and align them more closely with measured emissions to produce more accurate inventories. Accurate emission inventories enable operators to see the root causes of emissions more clearly and develop preventative practices and more efficient LDAR responses based upon that knowledge.

Continuous Monitoring Data Leads to Continual Operational Improvements and Better Emission Reduction Outcomes

Continuous monitoring data must be applied to operations on a strategic level to have a material impact on broader emission reduction goals over time. By implementing proactive workflows that compare continuous monitoring data with calculated emission estimates on an ongoing basis, operators can identify root causes of emissions and develop preemptive practices that yield accurate emission inventories, maximize LDAR approaches, and adjust alarm parameters to reflect actual site-level emission trends. Together, continuous monitoring data and proactive workflows help operators learn from instance to instance to improve operations and reduce overall emissions and regulatory exposure.

Reference:

- https://www.epa.gov/sites/default/files/2015-08/documents/ii10.pdf