Working to eliminate fugitive emissions is an ongoing process. Companies are developing new and innovative technologies every day to help in the fight against these emissions to reduce the risk to the environment and surrounding individuals.

Fugitive Emissions Journal sat down with Dr. Chris Kennell, VP of Sales – Americas, Oxford Flow, to discuss the daily activities of working with valves, the impact fugitive emissions have on the world, as well as his views on the future of the industry.

By Charlie Evans

Working with Oxford Flow for the past six and a half years, Kennell has moved through a variety of roles. “I started on the engineering team before moving into sales. Currently, I am the Vice President of Sales for the Americas,” he said.

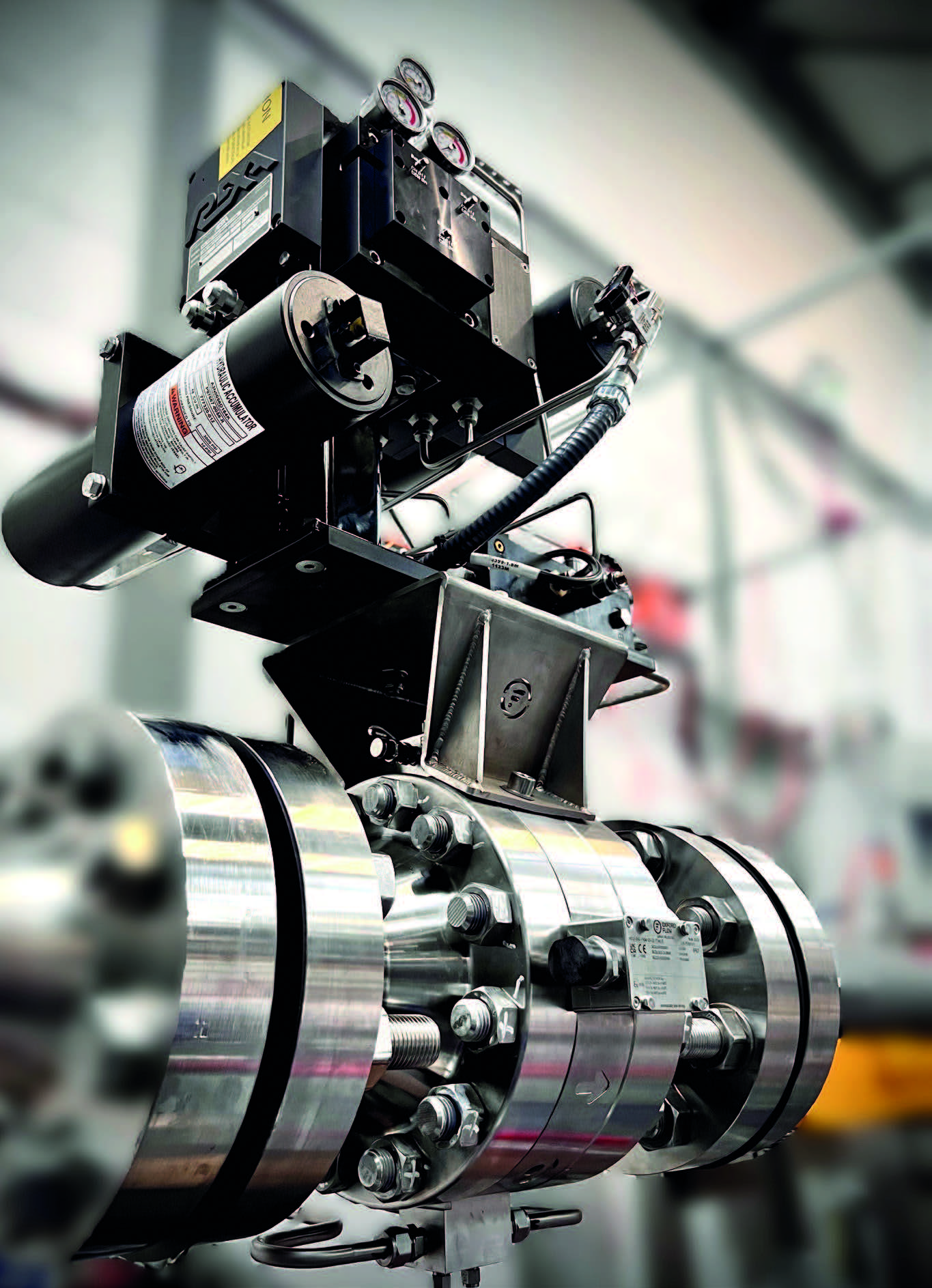

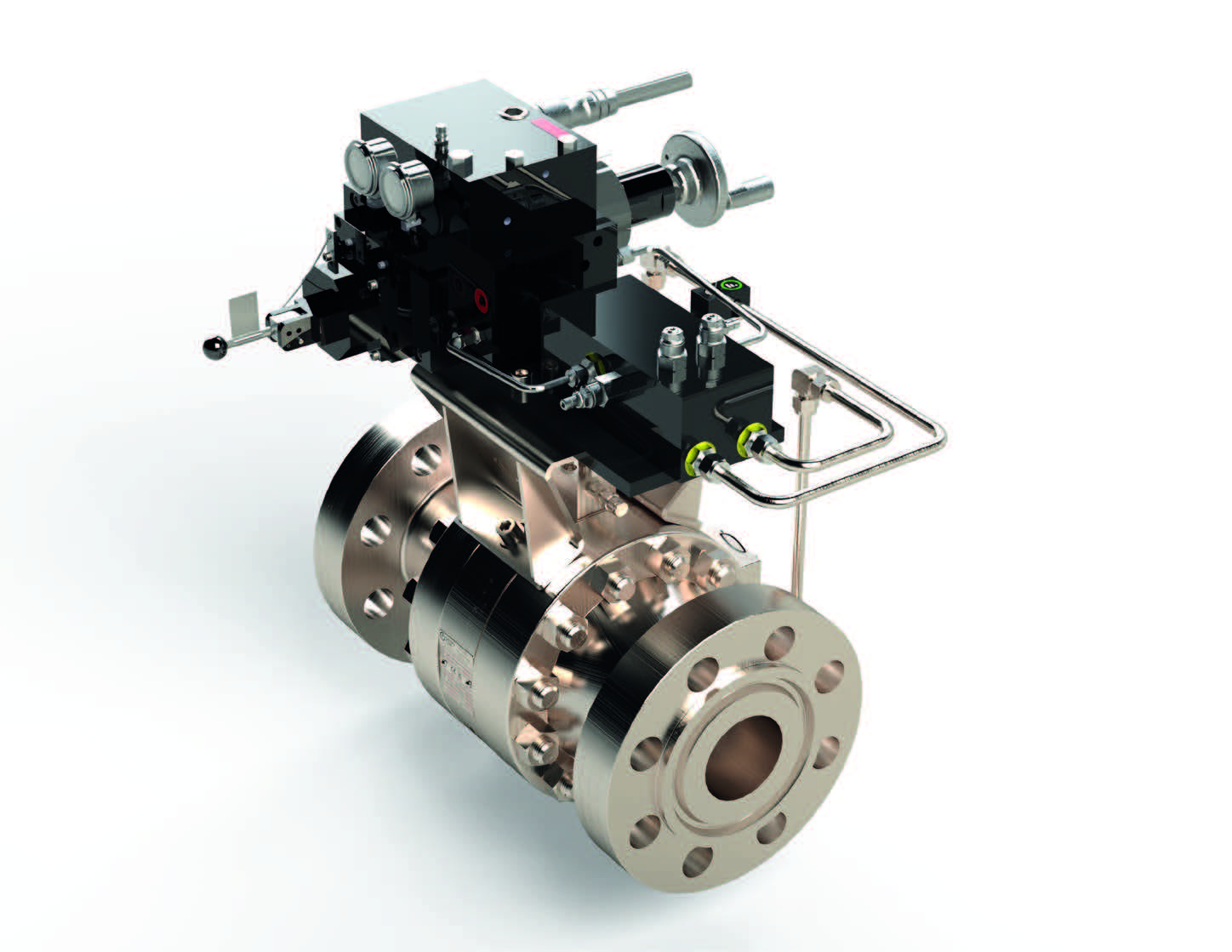

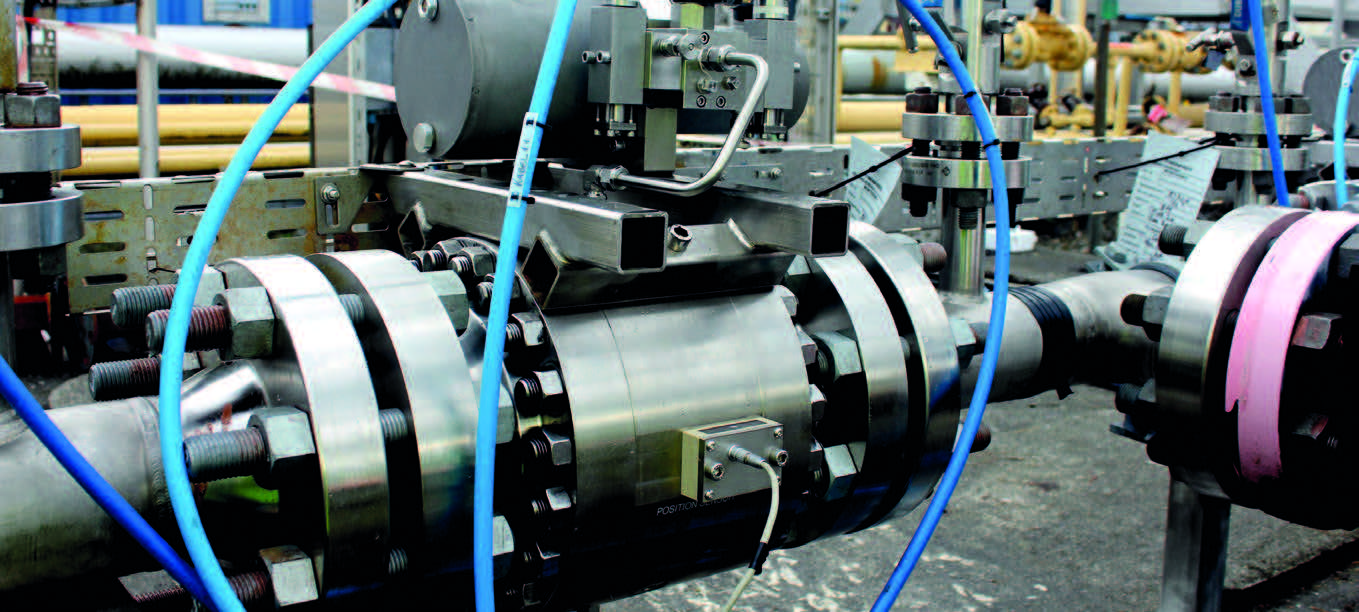

Primarily, Kennell works with pilot operating pressure regulators, as well as stemless control valves. “Oxford Flow was putting together a team to develop fresh and new designs that were not constrained by what was already out there. This allowed us to develop something inherently brand new that solved a lot of problems; namely our ES stemless valves.”

Working Day-to-Day

No two days are the same for Kennell. “I manage the Americas region, with a lot of our activity in Houston, TX. However, I go out and support our partners across the region in general,” Kennell explained. “We do a lot of work in Mexico with gas utilities. We are also working in Colombia and Canada.”

Traveling and working within the region allows Kennell to get in front of people and show them the developed technology. “One of the most fulfilling bits of the job is educating people about the newer technology. You can see the eye-opening moment when they realize that the technology is different and beneficial,” he continued.

Recently, Oxford Flow was nominated for the ADNOC Decarbonization Technology Challenge, allowing Kennell to travel to Dubai to participate and showcase their technology at the COP 28 Climate Conference. “We got to the final 10 out of 650 applicants and received a commendation for our ES Stemless Valve technology for its potential to decarbonize operations,” said Kennell.

New Valve Design

When replacing a traditional valve with a stemless valve, there is a significant decrease in fugitive emissions, as well as a predicted 20-30% reduction in the cost of ownership. “It is a simplified design that removes mechanical linkages. Fundamentally, without the stem and packing, there is only one moving piece. This leads to inherently no emissions.”

“I’m an engineer at heart, so having those engineering discussions about new technology adds a lot of value to the job,” Kennell relayed. “I get to be creative with products we have developed, like the ES stemless valve.”

“Bringing something new to an industry that is so conservative and risk-averse is not without its challenges,” continued Kennell. “When introducing something new, there is an associated timeline with that. It is great to have a close relationship with the end users and make them feel comfortable that the technology is going to work and continue to bring safety to their processes.”

Fugitive Emissions Regulations and Standards

Poorly monitored and controlled fugitive emissions pose a serious environmental hazard, as there are tons of harmful chemicals such as methane leaking into the atmosphere every year. “Methane is four times more potent than CO2 when it comes to emissions, and the industry is starting to come to terms with that,” Kennell observed. The Environmental Protection Agency in the U.S. (EPA) is continually developing and implementing regulations, allowing individuals to know their emissions better and tighten aspects of their operations. “The regulations highlight where the sore spots are in the industry.”

“Valves are a huge part of emissions. 60% of fugitive emissions come from valves, but when you look deeper into this, you can see that 90% of those emissions come from the stem and stem packing,” continued Kennell. “This is where the ES stemless valve idea was developed, as we eliminated stem packing. This means there are inherently no emissions from this technology.”

The regulations put forth by the EPA help highlight the big contributors regarding fugitive emissions. “The regulations play a fundamental role in helping out and reducing these bad actors across facilities, as it forces companies to highlight areas that are most problematic,” Kennell said. “I often meet with refinery managers and have a discussion about their most problematic assets to see if implementing new technology could be a better fit and have a less negative contribution to environmental emissions.”

.

Looking Forward

Currently, Kennell is working with major operators. “We have been engaging with many of the key operators and EPCs for the last few years to get feedback on our groundbreaking designs and ensure our products are fit for purpose,” explained Kennell. “We had to first develop concepts and prototypes and bring forth the voice of the customer into that development. Now we are at the stage where we have developed these great relationships, and we can bring them the new technology and deploy it to solve some of the problems that the end users face.”

When asked about the current working goals toward the reduction in emissions, Kennell said, “I believe everything is moving in the right direction. The industry is not going to shut down overnight, and everyone needs to understand that when looking at progress. We need to make it the best we can and make it environmentally friendly by deploying technology that works so we can achieve the decarbonization and net zero goals. We want it to be environmentally friendly and safer overall for everyone.”

“Do not be constrained by what is already done,” Kennell said when asked about advice for those looking to enter the industry. “You can think of creative solutions to problems. Think outside the box.”