In industries that push equipment to its limits—where searing temperatures, corrosive fluids, and abrasive slurries are everyday challenges—failure is not an option. Whether it’s a refinery under full load or a mining operation working with pressurized autoclaves, the key to operational reliability lies in materials engineering. One of the most promising advances in this realm is HVOF (High-Velocity Oxygen Fuel) coating technology, a powerful method for extending the lifespan and performance of critical components in severe service environments.

By Kelly Songer, Director of Valve Services, Precision Spray & Coatings

Protecting the Backbone of Industry

From petrochemical plants to power stations, chemical processing facilities, and mining operations, components such as valves, pumps, piping, actuators, seals, and gaskets are constantly exposed to aggressive service conditions. These components face a range of challenges, including abrasive wear from particulates in fluids, erosion caused by high-velocity flows, corrosion from acids, bases, and brines, thermal degradation due to elevated process temperatures, and mechanical stress resulting from high pressures and cyclic loading. In such environments, traditional materials often fail prematurely. That’s where HVOF coatings step in.

What Is HVOF Coating?

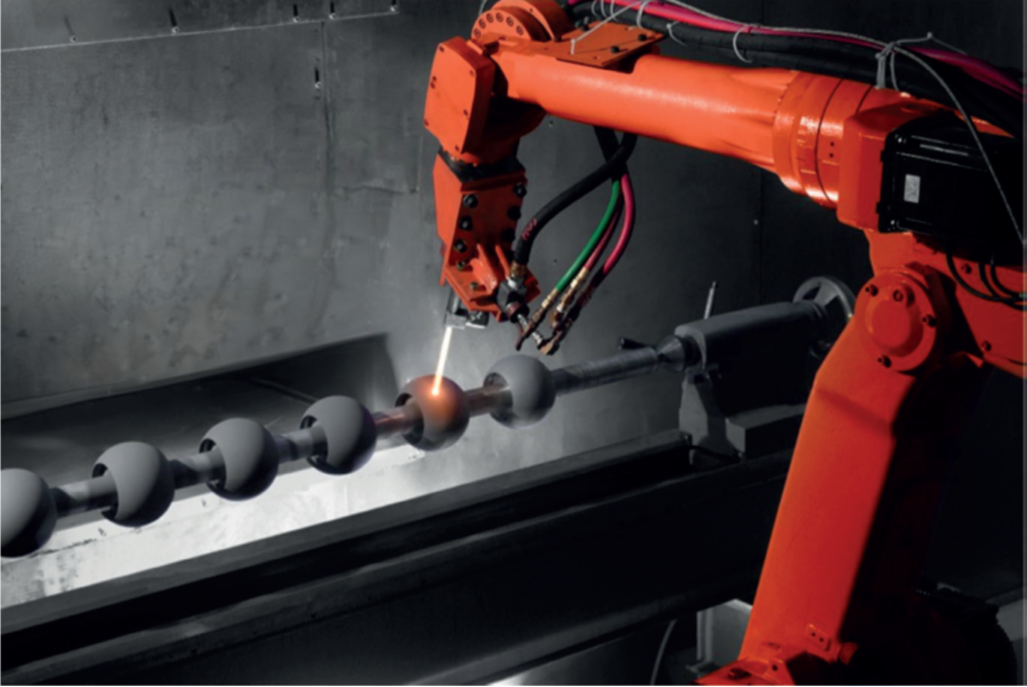

HVOF is a thermal spray process that creates dense, hard coatings by propelling powdered materials at high velocities onto a substrate.

A combination of fuel gases and oxygen generates a supersonic flame that melts or semi-melts the powder, which then bonds to the component surface with minimal porosity and excellent adhesion. This process allows manufacturers to create exceptionally durable coatings on components that operate in some of the world’s harshest environments.

Coating Materials

The materials used in HVOF coatings fall into three main categories: metallic alloys, carbide-based materials, and composites. Metallic alloys include nickel-based materials such as Inconel 625 and 718, as well as Monel, which are chosen for their heat and oxidation resistance. Cobalt alloys, such as Stellite 6 and 21, are prized for their wear and corrosion resistance and stability at high temperatures. Titanium alloys like Ti-6Al- 4V and commercially pure grades (Grade 2 and Grade 5) are used where strength, low weight, and corrosion resistance are required.

Carbide-based coatings provide even higher wear resistance. Tungsten carbide (WC) coatings are widely used in industries like mining and drilling due to their ability to withstand extreme abrasion. Chromium carbide (Cr3C2), on the other hand, excels in high-temperature environments and is common in the petrochemical, oil and gas, and cement sectors. These materials often achieve hardness ratings of 60 to 70 HRC on the Rockwell scale, offering superior protection against wear and erosion.

Composite coatings are engineered to blend hardness with toughness. For example, WC-Co (tungsten carbide with cobalt) combines ceramic hardness with the toughness of a metallic binder. WC-Ni offers similar wear resistance while improving ductility. Cr3C2-NiCr (chromium carbide with a nickel-chromium binder) is particularly effective at high temperatures and in corrosive environments.

Within this category, the balance of properties can be fine-tuned; for instance, a CrC 80/20 blend provides more hardness, while CrC 75/25 offers slightly less hardness but improved toughness and corrosion resistance.

Proven Benefits in Severe Service Applications

HVOF coatings offer a powerful suite of benefits for critical components. Their wear resistance protects surfaces from abrasion and erosion, significantly extending the service life of parts. They also provide excellent corrosion resistance, safeguarding materials against aggressive chemicals and environmental factors such as saltwater or acidic and alkaline media. In high-temperature environments, such as those found in power generation or catalytic processing, HVOF-applied chrome carbide coatings maintain hardness and mechanical strength, ensuring continuous performance under thermal stress.

Where Fugitive Emissions are Concerned

High Velocity Oxy-Fuel (HVOF) coatings play a critical role in reducing fugitive emissions, particularly in components that rely on tight metal- to-metal sealing such as valve stems, seats, and flanges. These coatings create exceptionally hard, dense, and smooth surfaces that significantly enhance the integrity of mechanical seals. The smoother finish, often with surface roughness values below 4 microinches (Ra) after precision grinding or lapping, minimizes microscopic leak paths that could otherwise allow gases or vapors to escape. This is especially important in high-pressure applications where even minute imperfections can lead to measurable emissions over time.

Beyond improving surface finish, HVOF coatings also offer outstanding resistance to wear and galling—common issues in dynamic components subject to repeated motion. For example, tungsten carbide-based coatings (such as WC-Co) provide a hard, durable barrier that helps maintain precise dimensional tolerances and sealing geometry even after extensive cycling. This resistance to mechanical degradation ensures that the sealing surfaces remain intact and functional longer than uncoated metals.

HVOF coatings also offer excellent thermal and dimensional stability, helping components maintain their shape and fit under fluctuating pressures and temperatures. This is particularly valuable in demanding environments like chemical processing plants or oil and gas facilities, where temperature swings and corrosive substances are common. By adding a layer of corrosion-resistant material—such as chromium carbide-nickel chrome (Cr3C2-NiCr)—these coatings prevent pitting and surface damage that would otherwise compromise the seal.

In essence, HVOF coatings significantly reduce fugitive emissions by preserving the critical interface between metal parts. Their combined resistance to wear, corrosion, and thermal degradation ensures long-term sealing performance and reliability, even under the harshest operating conditions.

Kelly is a 3rd generation industrial manufacturer with 20 years of experience. In 2016 she was featured in a cover story as a ‘Legacy Leader’ by the National Association of Manufacturers, and in 2017 she was honored with the ‘Service Award’ by the Valve Manufacturers Association of America. Kelly is Director of Valve Services at Precision Spray & Coatings.

Kelly is a 3rd generation industrial manufacturer with 20 years of experience. In 2016 she was featured in a cover story as a ‘Legacy Leader’ by the National Association of Manufacturers, and in 2017 she was honored with the ‘Service Award’ by the Valve Manufacturers Association of America. Kelly is Director of Valve Services at Precision Spray & Coatings.