It is widely acknowledged that small pipeline leaks are difficult to detect with traditional inline methods. This article offers a transformative approach to leak detection based on geospatial analytics that utilizes satellite imagery and AI-powered algorithms.

By Jay Almlie, Satelytics

Between 2002 and 2012, inline leak detection systems detected only 5% of all pipeline spills in the United States, according to analysis of federal Pipeline and Hazardous Materials Safety Administration (PHMSA) data. During this same period, the general public reported 22% of spills, while pipeline company employees at accident scenes reported 62%.

Even for highly significant spills exceeding 1,000 barrels (42,000 gallons), inline leak detection technology detected only 20% of incidents.

A more recent analysis from 2016 revealed that of 478 pipeline spills examined, only 105 (22%) were detected by advanced detection systems. The relatively low detection rate stems from the fundamental limitations of computational pipeline monitoring (CPM) systems, which excel at detecting large ruptures but struggle with smaller, slower leaks. According to pipeline specialists, 76% of leaks between 2002 and 2012 involved fewer than 30 barrels of oil (1,260 gallons), making them particularly difficult to detect remotely.

Average Discovery Time for Missed Leaks

When inline leak detection systems fail to identify leaks, the lag time for discovery can range from several days to multiple weeks. A well-documented case is the 2020 Colonial Pipeline spill in North Carolina, where a gasoline pipeline leak went undetected for eighteen days before two teenagers riding all-terrain vehicles discovered it on August 14, 2020. The pipeline had actually failed on July 27, 2020, and during those eighteen days, approximately two million gallons of gasoline spilled into the ground, making it the largest gasoline pipeline spill on land in U.S. history. Despite being designed to detect leaks as small as three percent of flow, the Colonial Pipeline leak detection system completely missed this release.

Similarly, in 2006, a large oil spill in Alaska’s North Slope went undetected for up to five days before an oilfield worker detected the scent of hydrocarbons. The spill released up to 267,000 gallons of crude oil across two acres. Most of the oil seeped under the snow cover, without triggering an alarm from the monitoring systems.

Slow-rate or intermittent seepage leaks can persist for extended periods without detection by real-time systems. These leaks may only be discovered through non-real-time balancing approaches that can take days or weeks to identify.

Shorten the Leak Discovery Lag Time

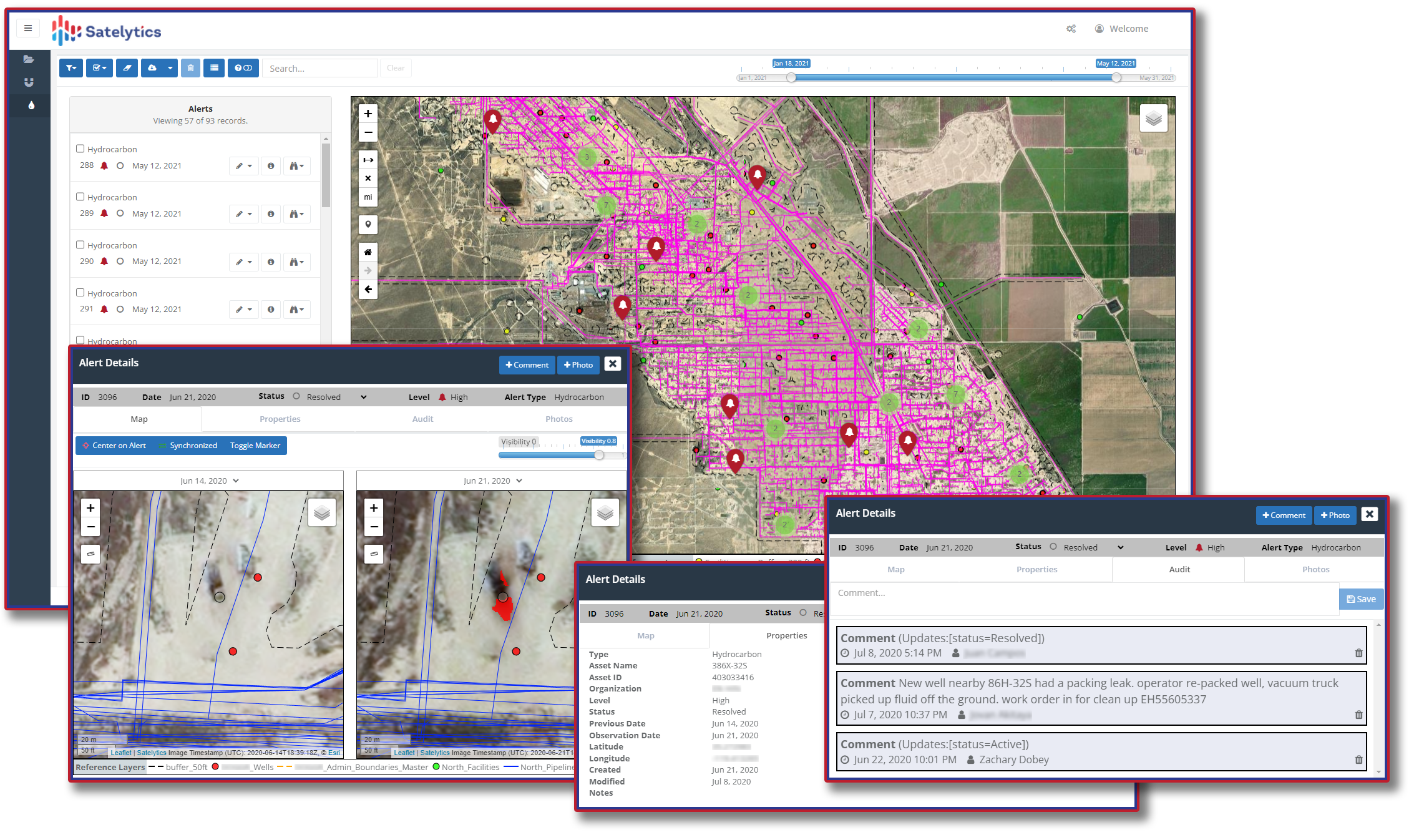

Geospatial analytics, utilizing satellite imagery and AI-powered algorithms, offers a transformative approach to reducing leak detection lag time from days or weeks to mere hours.

Satelytics can detect pipeline leaks too small for advanced inline leak detection systems to notice. We look for a surface expression of the leak and then deliver actionable alerts within hours of the satellite overpass. Modern high-resolution satellite imagery (30 to 50 cm resolution) can be captured daily. AI-powered spectral algorithms analyze the imagery to generate alerts that include specific location coordinates, leak size estimates, severity ratings, and asset identification. Some operators using this technology monitor their entire asset base multiple times per week, dramatically shortening the window between leak occurrence and discovery.

In the Williston Basin, our algorithms have been calibrated and tested over multiple seasons to detect liquid crude oil and produced water leaks in gathering systems and well pads. Leaks as small as a small puddle can be identified, enabling operators to catch problems early when operational, financial, and environmental damages are minimal.

Environmental and Reputational Damage Mitigation

Reducing detection lag time from weeks to hours dramatically minimizes several critical impacts:

- Environmental Protection: Early detection prevents small leaks from becoming environmental disasters. The Colonial Pipeline case demonstrated how an eighteen-day delay allowed two million gallons to contaminate soil and groundwater. Early detection enables intervention before underground leaks reach such a catastrophic scale.

- Cost Reduction: Smaller leaks mean smaller cleanups and lower remediation costs.

- Regulatory Compliance: Faster detection helps operators meet increasingly stringent environmental regulations and avoid penalties. Effective monitoring systems provide continuous documentation and compliance reporting capabilities.

- Operational Efficiency: The risk-based prioritization of leak detection efforts allows operators to concentrate inspection resources where they will have the greatest effect, rather than conducting blanket coverage.

Profit Protection

Lost product from undetected leaks directly impacts profitability. The ability to detect and respond to leaks within hours rather than days or weeks means:

- Reduced product loss: An eighteen-day leak at even modest flow rates can result in millions of gallons of lost revenue.

- Lower insurance premiums: Operators adopting advanced leak detection solutions report reduced insurance costs.

- Avoided emergency response costs: Proactive detection prevents expensive emergency mobilizations and crisis management expenses.

- Protected asset integrity: Early intervention prevents small issues from escalating into pipeline failures requiring major repairs or replacements.

Comprehensive Monitoring at Scale

To address a fundamental weakness of traditional inline detection systems, we recommend an approach that provides comprehensive coverage of entire pipeline networks. Form example, our system can monitor thousands of miles of pipeline infrastructure simultaneously, including remote or inac- cessible areas where ground-based inspection is difficult or impossible. This is particularly valuable for gathering lines and legacy well pads that often lack the SCADA investment of larger transmission lines.

Hence one of our clients reported that “several leaks would have remained undetected significantly longer without geospatial analytics alerts”, while field tests have demonstrated the ability to detect the smallest verified leak size of 0.029 gallons per minute with location accuracy within meters.

By transforming leak detection from a reactive process dependent on chance discovery to a proactive, data-driven system with near-daily monitoring, Satelytics fundamentally changes the risk profile for pipeline operators, protecting the environment, preserving reputation, ensuring regulatory compliance, and safeguarding profitability.