Everyone in the Leak Detection and Repair (LDAR) field, involving regulators, end users, and environmental service providers, consider OGI an essential and efficient tool for leak source identification in the campaigns.

By Francisco Cortes, Founder and CEO, SENSIA

In addition to extremely high sensitivity in the absorption bands of the targeted gases, OGI implements image processing that helps the surveyor enhance the gas visualization even in tiny leaks down to 0.1 SCFH in the case of cooled OGI.

One of the critical benefits of OGI vs. non-imaging technologies (sniffers, onboard sensors, lasers, satellites, etc.) is situational awareness of emissions sources. While non-imaging technologies require complex data retrieval algorithms involving third-party atmospheric data and modeling, which bring high levels of uncertainty and inexplicable reconciliation discrepancies (bottom-up vs. top-down data), OGI provides direct visualization of the emission source: irrefutable evidence.

Furthermore, thanks to the fact that OGI provides hardcore evidence about an emission or leak, nowadays, OGI is a common tool used by alternative technology manufacturers to verify the detection performance of the non-imaging technology.

OGI Technology in the IR Spectrum: MWIR and LWIR (thermal) vs. SWIR (non-thermal)

There is a wide range of OGI applications according to the targeted gases. For example, SF6, refrigerant, or ammonia are detected in the Long Wavelength Infrared (LWIR) which is from seven to 14 micrometers. Two different groups of technologies are sensitive to such wavelengths: uncooled (microbolometer arrays) and cooled (photovoltaic or photoconductive detector arrays).

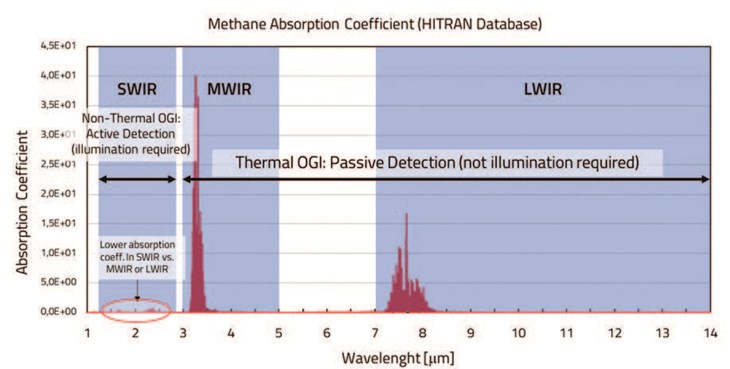

Many other molecules can be detected in the Mid-Wavelength Infrared (MWIR), which is from three to five micrometers. The most popularized OGI works in MWIR likely because the absorption bands of the VOC are located around 3.3 microns.

Both MWIR and LWIR technologies have one common detection principle: passive detection (no illumination sources are required to detect the gas leak/emission). MWIR and LWIR technologies are also known as thermal technology because the signal detected by the IR imager is based on the thermal emission/absorption of the bodies and gases. The most relevant condition for gas detection is the thermal contrast between the gas and its background (typically some dozens of mK). This feature makes MWIR and LWIR the most suitable OGI technology, because it delivers the best detection limit regarding Minimum Detectable Leak Rate (MDLR).

Alternative OGI technologies in the Short Wavelength Infrared (SWIR) are emerging for the specific case of methane detection (and some other few molecules). This wavelength has been demonstrated to be efficient for large emissions detection (metric tons per hour) since such big gas clouds produce enough radiometric contrast to be detected when the illumination conditions are good, for example, on a clear day with solar radiation. This is the principle used by satellites for methane detection. However, it presents multiple significant drawbacks when the intention of use is as a traditional OGI or as a continuous monitoring system. The most important ones are the following:

No passive detection: Illumination sources are required.

Operation limited to day and clear conditions or use of external illumination sources bringing complexity and high-power consumption rates.

Very weak absorption coefficient vs. MWIR or LWIR leads to much greater MDLR than MWIR or LWIR technology. SWIR OGI is a well-established technology for massive methane emissions detection from satellites, but it is not indicated for ground-level applications.

Until recently, the use of OGI has been fully focused on LDAR surveys. That is why the most popularized version of OGI is handheld. However, recent technological advancements in the Artificial Intelligence (AI) space allow for implementing AI-powered analytics to automate gas emissions detection and quantification.

These recent OGI techniques enable new precise approaches to detect, understand, quantify, and report Greenhouse Gas (GHG) emissions in oil & gas assets.

The advantages of an OGI-based continuous monitoring solution:

-

- To get accurate emission evidence through an OGI video without complex and unverifiable atmospheric models

- To correlate activity factors of components/sites with their emissions factors

- To inventory abnormal emissions

- Fully representative over time, emissions variability, intermittent sources, unintentional leaks, etc.

- To get a high-level understanding of the logic of emission with the highest degree of data granularity

- To get pieces of evidence of the methane emissions reduction strategies year over year

- To optimize and upgrade the operations and safety standards in assets. Additionally, for gas emissions monitoring, automated OGI can visualize the temperature of components, detect a flame, track people and vehicles on site, and measure the level of a tank.

Due to the wide range of benefits offered by automated OGI, operators can address sustainability goals with an unquestioned and long-tracked technology.

Technological Transition: From Single Point To Imaging Sensors

The power of imaging-based technology is huge. It can be realized by observing the evolution of surveillance applications. A solution based on a camera system (CCTV) is today, a very common and valuable way of protection, more so than sensors. In the end, a camera can be defined as an array of thousands (even millions) of single-point detectors, known as pixels.

By observing the way the industry protects its assets, its employees, its surroundings, and the environment, against most usual threats (flame, toxic gases, explosive atmosphere, etc.) it can be seen that single-point gas and flame detectors are vastly used. However, the latest technological advancements allow to convert an IR camera into a sensor. This step-forward is at the industry service to transform and upgrade the standards in operations, safety, and environment, saving cost, lives, and emissions.

The bulk deployment of continuous monitoring systems based on AI-powered IR imaging technology has just started in different industries. With the increasing number of unattended remote sites, new environmental regulations, and digital transformation, the penetration of this technology in Heath, Safety and Environmental (HSE) applications will scale at the same rate as visual cameras did in the past in surveillance applications.

An example of this technology is RedLook, an advanced and user-friendly OGI-based solution for continuous monitoring. One of the most extended cases of use of Red-Look is emissions monitoring within the oil & gas cycle because of its response to the most recent environmental standards coming from regulators and institutions such as OGMP. It allows monitoring and quantifying the emissions to be visualized and aggregated in a comprehensive data dashboard. It can be done in a cloud service, on-premises or the data can be shared directly to a third-party system for data management. Its IR imaging technology concentrates all the features that are demanded by the industry sector for the HSE challenges of today and the future.

ABOUT THE AUTHOR

Francisco Cortes is Ph.D. in Automation and Electronic and the founder and CEO of SENSIA. He has participated in several research programs related to advanced applications of Infrared Imaging in different fields such as aerospace, defense, safety, and environment. SENSIA is a leading manufacturer of infrared cameras and in the field of smart monitoring based on AI-powered infrared imaging.