Fugitive emissions are not a novel concern within the chemical processing and oil refining industries; however, they are an essential one. Emissions reduction has become a high-priority goal for virtually every process plant and facility in the U.S. Increasingly stringent government regulations and corporate environmental initiatives are strongly focused on reducing and eliminating service to the atmosphere. At the same time, improvements made to facilities are being made with truncated timelines and limited operating and capital budgets. Completely overhauling existing facilities with new equipment and technology can be a prohibitively expensive and time-consuming endeavor, leading many companies to look for smaller incremental improvements that can be implemented without significant disruption to existing operations.

Gaskets and valve packing can significantly impact fugitive emissions, as well as the life cycle costs of the equipment, making these an ideal focal point. Fugitive Emissions Journal spoke to TEADIT to learn more about how its gaskets and various innovative technologies help eliminate fugitive emissions.

By Sara Mathov

Understanding Fugitive Emissions

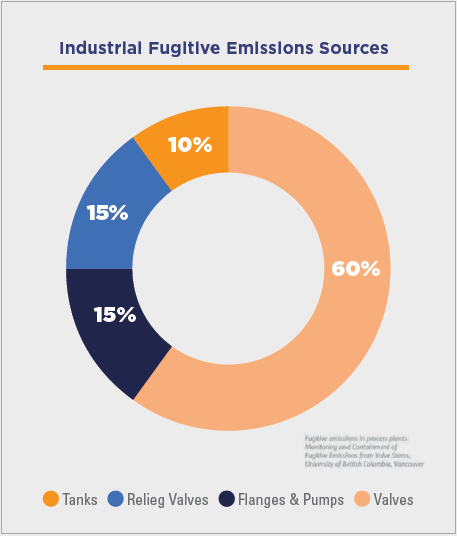

Fugitive emissions encompass unintentional releases of gases due to leaks from process equipment, including pumps, valves, flange connections, and storage tanks. These emissions primarily consist of volatile organic compounds (VOCs), such as methane, ethane, propane, and, periodically, benzene. VOCs not only contribute to global warming by absorbing infrared radiation from the Earth’s surface but also indirectly affect global warming by altering the concentration of ozone, a potent greenhouse gas.

Moreover, fugitive emissions can result in financial losses for industrial plants in the form of lost products and raw materials. Therefore, investments in leak reduction initiatives, such as leak detection and repair (LDAR), are both environmentally responsible and financially prudent.

Taking a Holistic Approach

Identifying the true cost of emissions can be complex, often due to a ‘silo mentality’ within organizations. Various departments, such as environmental, operations, engineering, and purchasing, have specific goals that sometimes conflict due to a lack of communication. For example, while the purchasing department may aim to reduce costs, they might not consider the total cost of ownership associated with implementing improved technology. A holistic effort that involves experts from various business units is essential to achieve meaningful change.

TEADIT has been working closely with industry and environmental experts to understand the genuine cost of emissions for its customers. The company has developed a Fugitive Emissions Cost Calculator, utilizing historical data from monitored sources and EPA leak rate equations, to quantify these costs and identify opportunities for savings

Calculating the True Cost of Emissions

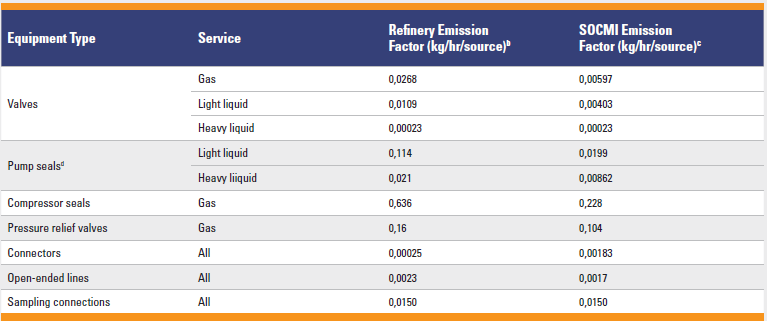

The following example involves a large refinery. If the refinery’s process was simplified and modeled as a single stream, it would likely consist of about 70% methane, 20% ethane, and 10% propane. A large refinery could have around 200,000 bolted-flanged joints that require sealing with a gasket, referred to by the EPA as connectors. Using standard reporting values for connectors per Refinery & SOCMI Average Component Emission Factors Table 2-6, this site would report 689 tons of emissions per year, resulting in associated losses.

The impact of these emissions is not just environmental but also financial. The following cost examples are in USD. These 689 tons of emissions would cost the refinery approximately $183,000 in lost products escaping to the atmosphere. Additionally, manufacturing facilities incur operating fees to federal, state, and local governments based on emissions, which can vary significantly by location.

Using a conservative state fee of USD $50 per ton, these emissions would cost the plant over $117,000 in fees. Furthermore, greenhouse gases, like methane, require an additional fee of $1,000 per ton. Considering that methane represents a high percentage of the process stream (70%), this would require an additional $482,000 in operating fees. The total annual cost for emissions from flange connectors amounts to a staggering $782,000 in expenses. These are not soft costs, but actually hard dollar costs that the manufacturing facility has to pay in lost product or operating fees.

What would happen if the facility used certified low-leak technology, such as TEADIT’s 913M spiral wound gasket? TEADIT designed the 913M to meet and drastically exceed the required sealing performance defined by ASME B16.20. This single change would significantly reduce emissions to 87 tons per year. Consequently, the loss of products and raw materials would decrease to $23,000, emissions fees to $15,000, and greenhouse gas fees to $61,000. The total cost would amount to $99,000, resulting in annual savings of over $682,000.

It is worth noting that annual savings of $682,000 is based on 200,000 connectors. Meaning, that the average savings per gasketed connection is over $3.00. With the average cost of a piping spiral wound gasket being less than $3.00 each, and if the gasket is a certified low-leak technology, the true cost of ownership becomes a net gain, with savings exceeding the gasket’s purchase price.

The Urgency of Reducing Fugitive Emissions

Global attention on fugitive emissions, including fugitive greenhouse gases, has led to increasingly stringent regulations. These regulations are enforced rigorously, with environmental agencies conducting frequent inspections and imposing significant penalties on non-compliant companies.

Notably, the EPA has incorporated consent decree agreement language, focusing on connectors, into its updates to gasket standards like ASME B16.20. Consent decrees typically require specific actions within a specified timeframe to achieve environmental compliance. Failure to comply results in civil penalties, including hefty fines. Companies must involve procurement departments and supply chain management to ensure compliance, as regulations now demand low-emission technology for equipment and gaskets sourced for future maintenance, repair, operations, as well as new projects.

Addressing fugitive emissions is no longer optional. New EPA standards and consent decrees necessitate immediate action. Non-compliance can lead to severe fines, and these penalties escalate rapidly for repeat offenders.

Investors and stakeholders now demand that companies engage in environmental improvements and demonstrate their progress. By reducing fugitive emissions, companies can proactively respond to climate change with tangible actions and measurable results. Eliminating fugitive emissions becomes a business responsibility, and companies face increasing pressure to stay competitive in a greening economy.

The Multifaceted Costs of Fugitive Emissions

The expenses associated with fugitive emissions and leaking utility streams extend beyond immediate product losses. While every pound of escaped material represents lost revenue, these costs encompass raw material expenses and the resources invested in producing the lost material. Additionally, poorly performing leak detection programs result in increased maintenance and operating costs. Furthermore, regulatory violations incur fines, which can be substantial and escalate rapidly for repeat offenders.

The Path Forward – An Investment in Tomorrow

As the world progresses toward net-zero emissions, companies must adopt new emissions management strategies. Regulations will demand a shift in emissions management paradigms. Forward-thinking companies are embracing low-emission technology to reduce and eliminate fugitive emissions. By controlling fugitive emissions, or LDAR initiatives, all industries can become better stewards of the environment and simultaneously achieve significant cost savings.

TEADIT’s low-emission solutions, such as improved gasket standards and valve packing designs, along with training on flange connection and valve reliability best practices, offer a path to significantly reduce fugitive emissions. By installing low-leak technology, such as ‘low emissions’ gaskets and valves designed to minimize fugitive emissions, companies can achieve emissions levels never before seen. These solutions not only contribute to environmental sustainability but also ensure a substantial return on investment (ROI) by keeping products in the pipeline.

In conclusion, the urgency to reduce fugitive emissions is clear. Regulatory pressures, investor demands, and environmental responsibilities all point towards a concerted effort to minimize emissions and environmental impact. TEADIT’s low-emission solutions provide a pragmatic and cost-effective path to both environmental responsibility and financial gain. By embracing these solutions, companies can reduce emissions, comply with regulations, and secure their position in a greener future.