#1) Tailor your LDAR plan to your facility. A good LDAR plan will have a brief scope and overall description of your site and the process units. It should have a link to a copy of the sites air permit and a breakdown of what federal or state regulations govern your site.

#2) Include a list of all personnel involved in your LDAR program – Have a quick list of all users, their contact in-formation, and what their roles and responsibilities will be. Examples of this would include, “Who handles MOC’s (management of change)?,” “Who does the tagging and documenting for new equipment?” and “Who takes care of LDAR leaks and signs off on Delay of Repair paperwork?”. Having a detailed plan with a list of key personnel roles will eliminate confusion and help sim-plify one’s duties and responsibilities.

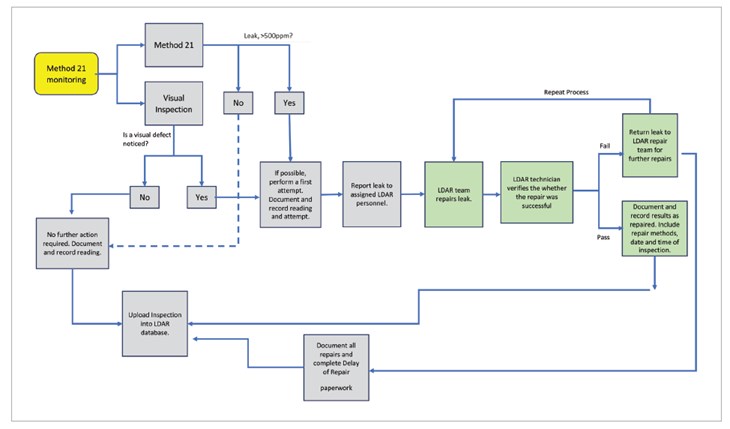

#3) Does your plan include a workflow chart? Your plan should include daily workflow charts for items such as daily calibrations, Method 21 monitoring, and uploading data into your LDAR database. It should also dictate how you conduct QA/QC of your data before and after its processed into your LDAR database, what daily reports need to be generated, drift check assessments and calibration documentation.

Scenario 1: Your LDAR technician comes in at the end of the day and completes his end of day drift assessment. He notices that his analyzer has a greater than 10% negative drift. What should he do? Your plan should have a section for how your techs are to handle this situation, who is to be notified and what equipment is to be retested.

Scenario 2: Your LDAR technician has completed his Method 21 monitoring on a component that is found leaking. If a regulatory leak has been determined, your plan should include, how and what type of repair should be made. What repair information will be recorded in their handheld, and any follow up inspections.

What are my leak repair requirements?

When a leak is found each regulation has a standard method of repair for different types of equipment. Your plan should include how and when a first attempt and final repairs are to be completed, when follow up inspections are made, and when to remove a leak tag.

Did you know that when you label a component as DTM (difficult to monitor) or UTM (unsafe to monitor) that LDAR regulations require you to have a plan of how to monitor these items? For example, HON -§ 63.181(b)(7)(i) Identification of equipment designated as unsafe to monitor, difficult to monitor, or unsafe to inspect and the plan for monitoring or inspecting this equipment. Alternatively, NSPS VV – § 60.482(h)(3) says, the owner or opera-tor of the valve follows a written plan that requires monitoring of the valve at least once per calendar year. So, de-pending on what regulation your facility falls under, you will need to have a plan that dictates how and when you will monitor these components.

How long should I retain my LDAR records?

All LDAR records in your plan should be maintained for at least 5 years. Records of all required monitoring data and support information, including calibrations, maintenance records, training records and copies of all reports required by the Division for Air Quality, shall be retained by the permittee for a period of five years and shall be made available for inspection upon request by any duly authorized representative of the Division for Air Quality. Training for all personnel involved in your LDAR program should be documented and kept, readily available for inspectors.

Do you have the right plan?

Ed Diaz is a LDAR SME with over 25 years of experience dealing with environmental compliance, with 20 of those years being specifically in LDAR for chemical plants and refineries. Ed has worked in various Consent Decree programs, as well as Enhanced LDAR programs. He specializes in HON and MON LDAR programs. Ed has completed LDAR monitoring, reporting, training, project setup, database startup/management, tagging, and audits within the chemical industry. He has an extensive regulatory knowledge and has developed internal auditing/training programs.

Ed is currently the Manager, of LDAR Services for PROtect and overseas all the daily compliance activities, and is currently based in Louisville, Ky. He ensured overall compliance for his facilities, and has a ZERO NOV mentality Ed has a reputation for taking care of his clients and doing what needs to be done, to get the job completed.