By Gary Vegh, Co-Founder & Chief Toxicologist, Erin Manitou, Senior Project Analyst & Managing Partner and Nora Lopez, ERA Toxic Release Inventory & Compliance Expert

What happens to the data once it is submitted? How is it used?

• First, it is important to be aware that the information provided to these agencies is used to estimate risks and to measure the progress of climate-related goals.

• Secondly, there is a liability issue if the information is not accurate.

Using Reported Data for Risk Estimation

Organizations reported emissions data is reviewed and made available to the public via websites such as EPA’s Envirofacts and Enforcement and Compliance History Online (ECHO). Toxic Release Inventory (TRI) data is open to the public through the TRI Explorer platform. The reported air emissions data (stack and fugitive air emissions) are used to determine related risks associated with their release. Figure 1 highlights two tools that look at air emissions and their associated risks1,2,3,4,5:

Liability Issues from Inaccurate Reporting

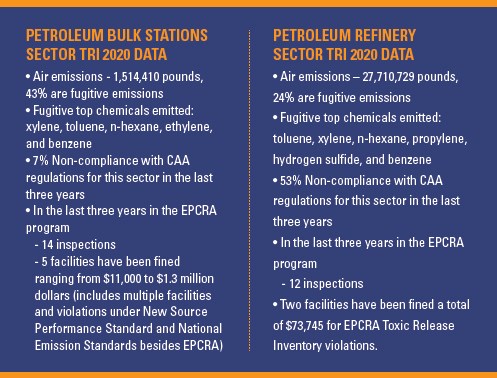

Oil and Gas industries must provide accurate and auditable information regarding the tank emissions reports provided to government agencies. The EPA reviews the data, cross-references information with permit emission requirements to address inconsistencies. They select which facilities to audit based on the information supplied and discrepancies between the data provided to different state and federal agencies. For example, they compare state-level emissions inventory with GHG emissions reported at the national level, discrepancies between quantities of natural gas emissions burned can trigger agency audits. Figure 2 shows an example of fugitive emissions reported to TRI for Petroleum Bulk Stations and Petroleum Refineries and includes EPCRA TRI penalties issued in the past three years3,4,5,6,7:

It is important to understand that fugitive emissions are considered during EPA’s review of the data, and emission calculations should be as accurate as possible. A facility can save vast amounts of penalty fees by accurately reporting all of its emissions, including the fugitive tanks emissions. With the increasing need for emission reduction and robust emission reporting requirements, industrial chemical processors and manufacturers must carefully monitor, calculate, and report their emissions.

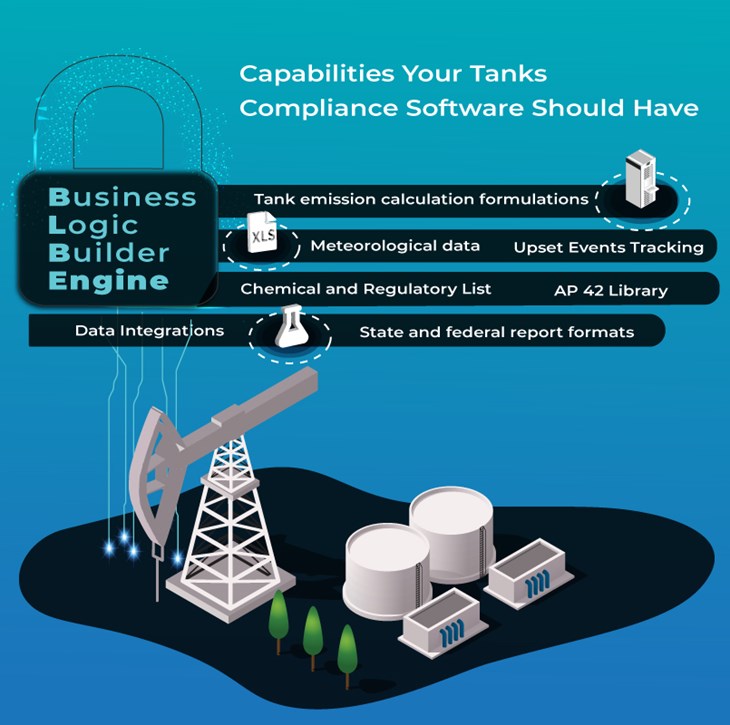

To achieve better accountability, an effective Tank Emissions Software will be required. However, selecting the right software for the industry calculations requires screening for several factors. The ultimate Tank Emissions Software should have:

• Built-in AP-42 (Chapter 7) and API library with standards and calculations.

• Coverage of your specific process types.

• Inclusive Meteorological Data.

• State and federal regulatory reporting formats.

• Permit Compliance Reporting.

• Tank data upload templates.

• Integrated chemical and regulatory lists

• Practical QA/QC tools.

AP-42 Chapter 7 provides effective emission estimation methodologies that cover all potential tank scenarios within a given facility. To correctly manage air quality, the API conducted numerous studies to formulate accurate equations for calculating emissions. They tested everything ranging from deck fittings, rim seals, wind speed, and varying ambient air changes and formulated standardized calculations for emissions estimates. Having a built-in AP-42 library makes the tank emissions tracking process seamless.

One of the important software features is the ability to cover a specific process type. For example, oil refineries have processes such as distillation, mixing, loading, and packaging that contribute to emissions, while oil exploration plants that use equipment such as gas lines and dehydrators that can uniquely cause emissions. These process types also use different tank types that are all affected differently by the climate. Tanks in a hot environment are more likely to lose emissions because the heat makes the stored liquid volatile, and gasses are emitted due to breathing losses and heat expansion. Colder climates are less likely to experience this. Inclusive meteorological data within given software would help mitigate such calculation nuances.

After data calculation and compilation, the software must provide various state and federal regulatory reporting formats and tank data upload capabilities. Reporting formats sometimes vary by state; for example, National Emissions Inventory (NEI) reporting is different in each state, and facilities must submit the report according to their state requirements. Other reports such as Toxics Release Inventory (TRI) have universal upload systems, which means the chosen software should out-put data that can be readily uploaded to the platform.

Integrated chemical and regulatory lists are the backbones of emissions reporting software because the chemical is the basis of emissions calculations. Liquids have variable molecular weights, density, and vapor pressure, which dramatically affects how readily vapors are released from the surface of the liquid into the atmosphere. Some emissions from certain liquids may seem negligible but are cumulatively significant in reporting emissions. Having a built-in chemical list will provide all these variables for effective tank emissions calculations.

Good QA/QC tools in filing federal/state reports can provide a complete account of how the software arrived at that emission value and cross-reference a users report with previous reports. If the calculation is inaccurate, this is shown by a significant deviation from other values. Data discrepancies can help operators vet your data while also allowing them to notice an increase in emissions.

Overall, using Tanks Emissions Software is sure to keep your organization accountable and stay on top of emissions calculations. Accurate reporting helps the federal government effectively plan for the future while also helping facilites steer clear of compliance fines and inaccurate data emission estimates.

For example, ERA’s Tank emissions software covers all tank scenarios and incorporates all the required calculations and reporting requirements for various recordkeeping time intervals.

The QA/QC capabilities include cross-referencing NEI and TRI data to avoid discrepancies. The software covers all tank types and processes, making it an ideal solution for tank emissions reporting.

Overall, using a software solution is the best way to stay on top of tank emission calculations and reporting. Accurate emissions reporting will effectively help with the United States and Canada air pollution reduction goal.

For more information, please visit: http://www.era-environmental.com/

1. Environmental Protection Agency. (n.d.). Envirofacts Home. EPA. Retrieved November 4, 2021, from https://enviro.epa.gov/.

2. Environmental Protection Agency. (2021, November 3). Enforcement and Compliance History Online. EPA. Retrieved November 4, 2021, from https://echo.epa.gov/.

3. Environmental Protection Agency. (n.d.). EPA. Retrieved November 4, 2021, from https://www.epa.gov/national-air-toxics-assessment.

4. Environmental Protection Agency. (n.d.). EPA. Retrieved November 4, 2021, from https://enviro.epa.gov/triexplorer/tri_release.chemical.

5. Environmental Protection Agency. (n.d.). EPA. Retrieved November 4, 2021, from https://www.epa.gov/rsei.

6. Environmental Protection Agency. (n.d.). EPA. Retrieved November 4, 2021, from https://edap.epa.gov/public/extensions/TRISearchPlus/TRISearchPlus.html#continue.

7. Solutions, E. R. A. E. M. (n.d.). Free ebook: Storage Tank Emissions: ERA environmental. Free eBook: Storage Tank Emissions | ERA Environmental. Retrieved November 4, 2021, from https://lando.era-environmental.com/the-science-of-tanks-emissions.

8. Environmental Protection Agency. (n.d.). EPA. Retrieved November 4, 2021, from https://www.epa.gov/toxics-release-inventory-tri-program.

About the Authors

Gary Vegh is a recognized speaker and educator who works with international manufacturing associations to advise on issues of sustainability, supply chain issues, and advanced compliance strategies. Gary holds a Master’s Degree in Environmental Toxicology from Concordia University and is an active member of the Society of Toxicology, the American Coatings Association, the Chemical Institute of Canada, and the Supplier’s Partnership for the Environment. He has over twenty-six years of expertise in the compliance and environmental sustainability fields, with experience as a consultant, a software solution architect, and entrepreneur.

Erin Manitou holds a Master of Science degree in Environmental Science from the University of Texas at San Antonio (2008). She has 13 years of experience with ERA Software Solutions assisting businesses improve and protect their environmental, health & safety and sustainability management through advising, generating federal and state compliance reports, permit amendments, and implementing the ERA-EHS platform for numerous organization. Erin Manitou is the recipient of many grants and scholarships, including awards from the Center for Water Research, the Bexar Metropolitan Water District Grant, and the American Association of University Women Scholarship. Erin Manitou also holds a Bachelor of Science in Zoology (2001) from University of Texas at Austin.

Nora Lopez was the Toxic Release Inventory Coordinator (US Pollutant Release and Transfer Registers) at the US EPA for Region 2 since the program started in 1986. Nora has a B.Sc. in Chemistry and a Master’s Degree in Public Health from the University of Michigan, with a concentration in Environmental Health. Nora has developed and implemented regional EPCRA Section 313 technical guidance and compliance assistance outreach activities for industry, state, local agencies, and the regional office. She has reviewed emissions data provided to the EPA by facilities and has substantial experience with enforcement activities. She works closely with ERA’s environmental science team as a consultant, creating expert educational courses and leading training sessions in EPCRA, Tier II, TRI, and auditing.